Select language

About VDL Olocco

Founded in the 1950s by Tommaso Olocco, the company initially focused on plant maintenance and the construction of wooden mills and mechanical handling.

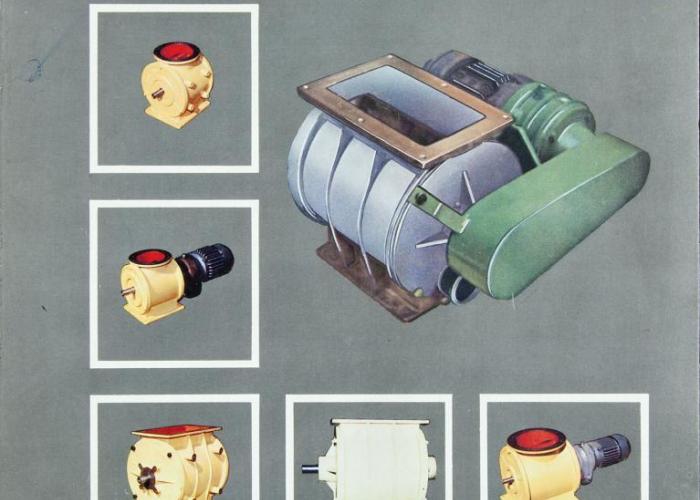

In the mid-1960s, the company passed into the hands of his son Mario Olocco, and by the late 1970s, thanks to the experience gained in the bulk material systems sector, the business began its first production of valves and mechanical components. This was a simple production of three models, produced in batches of just a few dozen pieces per year.

In the early 1990s, Olocco moved to its current industrial site in Fossano, installing its first CNC machine tools.

At the turn of the century, his children Andreana and Umberto joined the company, and remain involved in the business to this day.

Since 2015 and consistently thereafter, huge investments have been made in new production technologies and new production spaces, which continue to this day.

In October 2022, Olocco joined VDL GROEP BV, a family group of more than 100 manufacturing companies in a wide variety of applications.

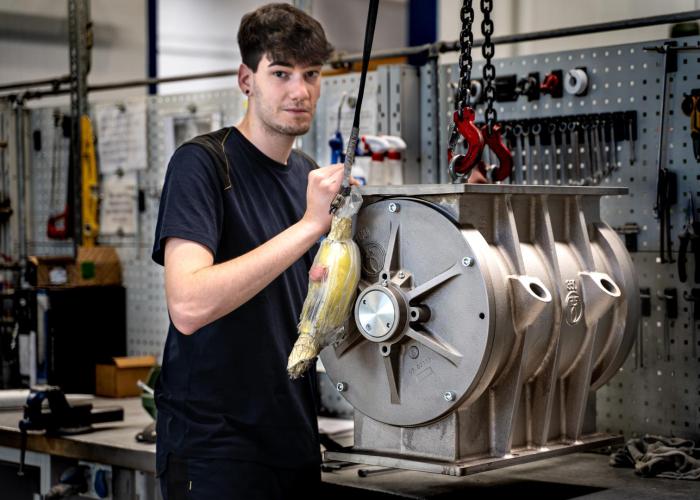

The company currently produces thousands of components annually and exports them worldwide thanks to a consolidated network of customers and dealers.

A group, a family, a company

in continuous growth

VDL OLOCCO employs a 4.0 production department with state-of-the-art 4- and 5-axis multitasking machining centers, allowing us to produce medium-large production batches as well as valves made to customer specifications.

Considering the various valve families with their respective sizes and the numerous types of materials and treatments, our catalog offers over 2,000 different versions. Nevertheless, every year our R&D department focuses on new types and innovative treatments.

In our department, we design all our products with state-of-the-art 3D CAD programs and utilize technologies and software for the most demanding applications, such as those involving high temperatures.

VDL OLOCCO has always designed and manufactured its products based on the core principles of quality, functionality, and reliability. The company has been certified UNI EN ISO 9001:2015 since 1997, demonstrating its ongoing commitment to excellence in production processes.

VDL OLOCCO’s product range can be certified in accordance with the ATEX Directive 2014/34/EU, making it suitable for use in potentially explosive atmospheres.

In the food industry, the company ensures the food-grade compliance of its components in accordance with Regulation (EC) No. 1935/2004 (MOCA), concerning materials and articles intended to come into contact with food, and Regulation (EC) No. 2023/2006, which governs good manufacturing practices for such materials.

Since 2025, VDL OLOCCO has been awarded the EcoVadis Certification, internationally recognized as one of the most widely adopted standards for corporate sustainability assessment, with over 100,000 companies evaluated worldwide.

This certification marks a significant milestone in VDL OLOCCO’s commitment to responsible and sustainable business practices. It involves a thorough evaluation of key areas such as environmental impact, ethics, human rights, and sustainable procurement, highlighting the company’s dedication to transparency and its active contribution to a more sustainable future.